Wallpaper provides beautiful, paper-based decorations for the walls and ceilings of families’ and individuals’ homes, as well as public spaces like restaurants, hotels, and commercial facilities. It is a major element of staging decor that accounts for a considerable proportion of the surface area involved in decorating interiors, and so could be considered the most familiar interior design material associated with today’s living spaces. While people may not ordinarily be conscious of wallpaper, it comes in a diverse range of forms, with an array of different colors, patterns, base materials, and textures. The kind of wallpaper people choose can even improve the quality of their lives. To take a closer look into the profound appeal of these products, we visited a wallpaper manufacturer based in Noda City, Chiba Prefecture.

Used to cover rooms’ walls and ceilings, wallpaper is an indispensable interior finish material for enriching people’s lives. The types of wallpaper available number in the many thousands, offering innumerable combinations of designs, colors, and materials. These range from simple, unpatterned designs that blend in harmoniously with Japanese living spaces to woodgrain and stone-like finishes evoking real natural materials, as well as styles impressively reproducing the textures and feels of fabric.

3A Co., Ltd., a company headquartered in Noda City, Chiba Prefecture, specializes in the manufacture of original wallpaper products, using not only established techniques and materials, but also incorporating artistic approaches, flexibly adopting methods of expression to meet the needs of the time.“There are actually few countries in the world where wallpaper is used to the extent that it is in Japan,” Tomoaki Maruyama, president and CEO of the company, tells us. “In places like the US and Africa, it is more common to apply paint directly to walls, as you might see in Western films where the father is painting the walls on one of his days off. There are various factors related to this, but one is the difference in climates. While in a country like Japan, where the humidity is high, applying paint to concrete can cause mold due to issues like condensation, this is not a concern in countries with warm, dry climates. Paint is also more affordable and relatively easy to apply, plus there is a growing DIY culture that values taking home maintenance into one’s own hands. I think those are reasons why paint is commonly chosen overseas.”

According to data the Wall Decoration Study Circle released in 2022, annual Japanese wallpaper shipments amount to 670 million m2 annually, in terms of total area, giving Japan a third-place ranking worldwide, following only China (1.8 billion m2) and Russia (950 million m2). Japan is a major producer and consumer of wallpaper, accounting for about one-sixth of the world market. Wallpaper is also widely used in Europe, where there is a long-established culture of decorating interior spaces. While there the tendency is to emphasize its design characteristics, in Japan there is more of a focus on its functionality. It seems that views of wallpaper as part of lifestyle-oriented fashion decor may have contributed to the development of wallpaper culture.

According to the materials used for it, wallpaper can be classified into a number of types. There is paper-based wallpaper, which may be made from washi or plain paper, fabric-based types made from textiles including rayon, silk, and hemp, plus plastic-based products, inorganic forms and more. In Japan, around 99% of the wallpaper actually used is coated with polyvinyl chloride resin.

“Previously, wallpaper made of cloth was most commonly used in Japan. As the use of materials like gypsum board became more prevalent in the postwar period, however, there was a shift to using more durable vinyl wallpaper to protect such structural materials,” President Maruyama comments.

Japan’s period of rapid economic growth brought increased demand for housing, and the construction of multi-unit apartment and condominium complexes provided a large supply of rooms with uniform designs. This, it seems, caused an explosive boom in the use of low-cost, easy-to-apply vinyl wallpaper.

“Vinyl wallpaper offers a high degree of freedom of expression and surface treatments can be easily applied to it. Vinyl materials have excellent fire resistance and fireproof properties and can be supplemented with various other functional properties, including stain resistance, deodorant effects, mold resistance, and antibacterial properties,” explains President Maruyama.

3A Co., Ltd. has continuously produced a diverse range of wallpapers, with a focus on vinyl wallpaper, since its establishment in 1982. Spanning a half-century, the company’s history has progressed alongside the wallpaper market’s period of development.

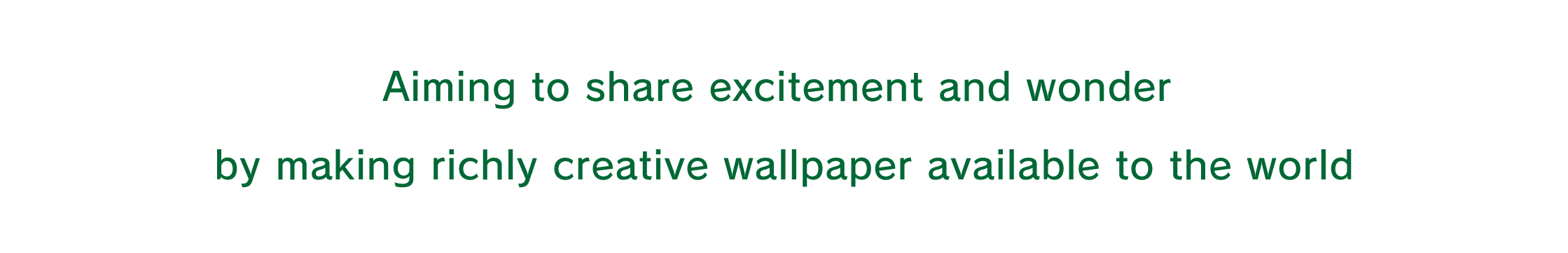

Mother rolls 2,000 m in length,

coated with resin and sorted by product

type.

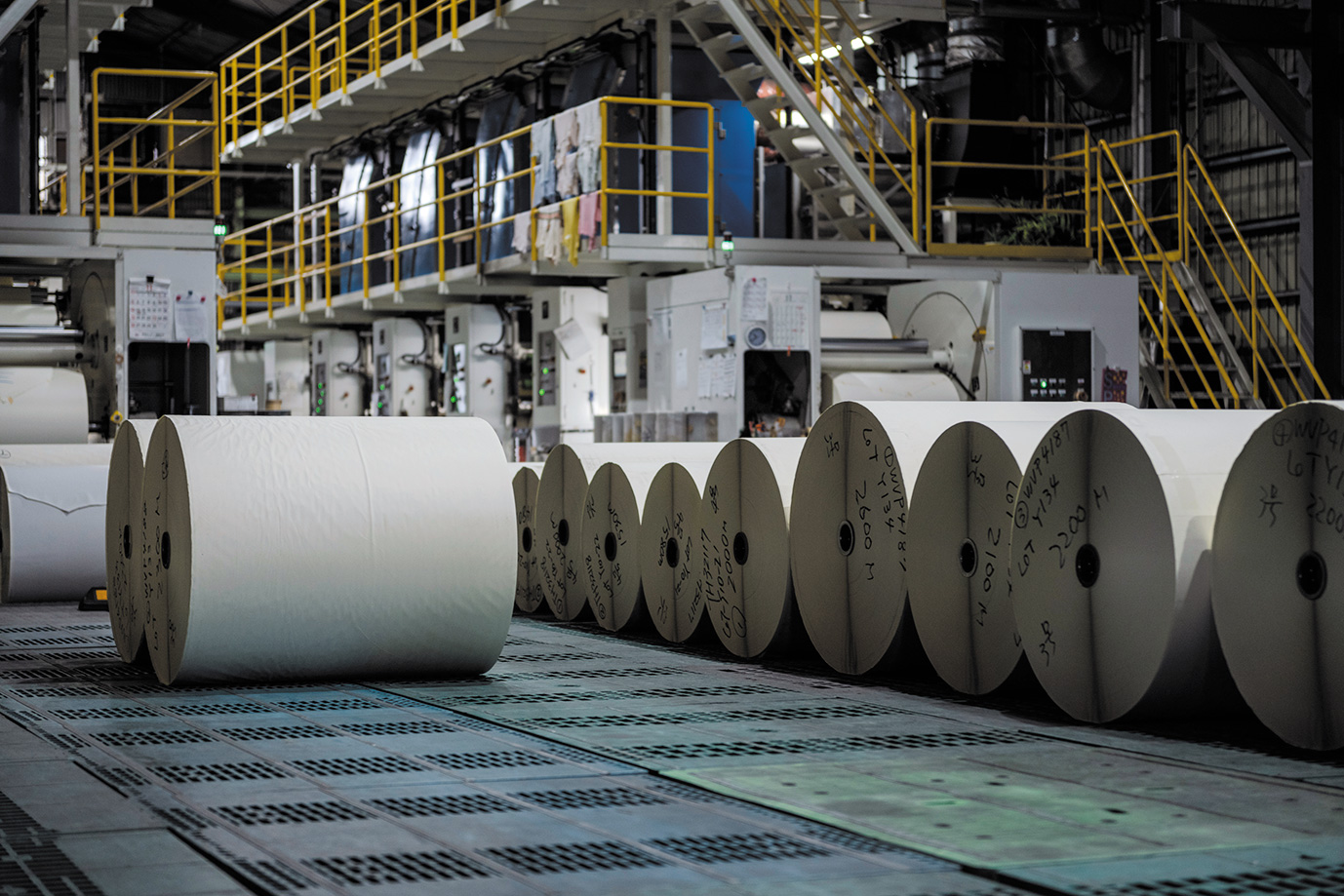

Wallpaper designs being applied by

gravure printing.

A laser-engraved embossing roll.

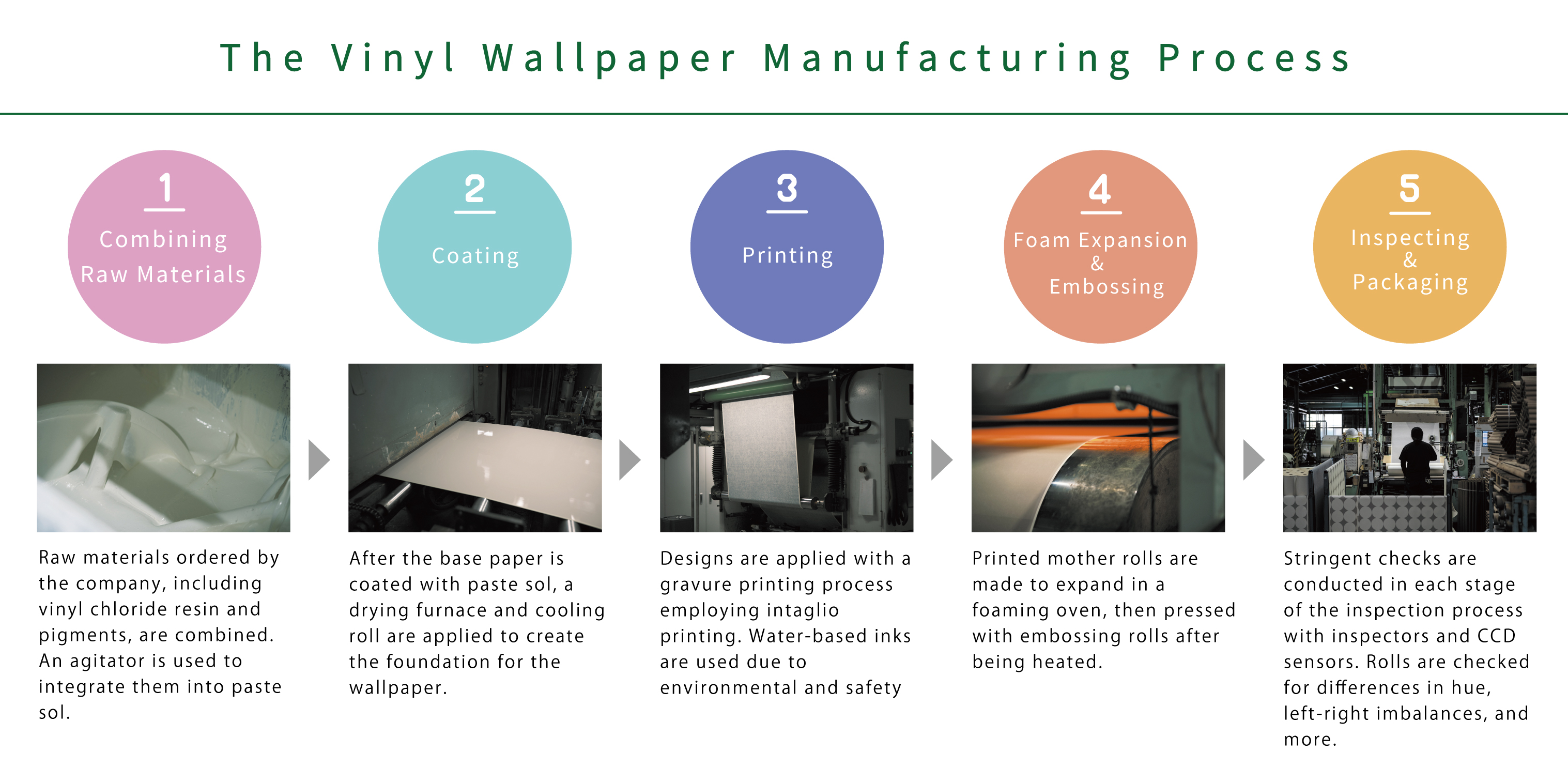

3A Co., Ltd. maintains three production facilities, where it handles all stages in-house, from the manufacturing process — combining the crude raw materials, printing, embossing, and more — all the way up through shipping the final products. Our reporting team observed the company’s vinyl wallpaper manufacturing process, guided by President Maruyama’s commentary.

First, we traveled to the Kimagase Factory, where materials for wallpaper totaling 10,000 m in length are stacked high. The company says they order paper they have selected to be easy to apply and that will peel off neatly, including the glue, with thin plain paper (65–70 g/m2) used for the mother rolls. They use as much as 30 million m2 annually. A paste made by mixing vinyl chloride resin and other materials is used to coat the paper before being dried.

Gravure printing is then used to apply patterns and designs. Next, a foaming agent contained in the printed mother rolls is made to expand at high heat (200°C or above), and three-dimensional patterns with uneven surfaces are created by pressing the paper with embossing rolls.

“One of the key demands for our company is to produce beautiful textures with our embossing processes. We use laser-engraved embossing rolls to achieve designs featuring greater complexity and subtle detailing. We’re dedicated to delivering the most beautiful nuances and shadowing revealed by light — expressions of the utmost profundity,” President Maruyama comments.

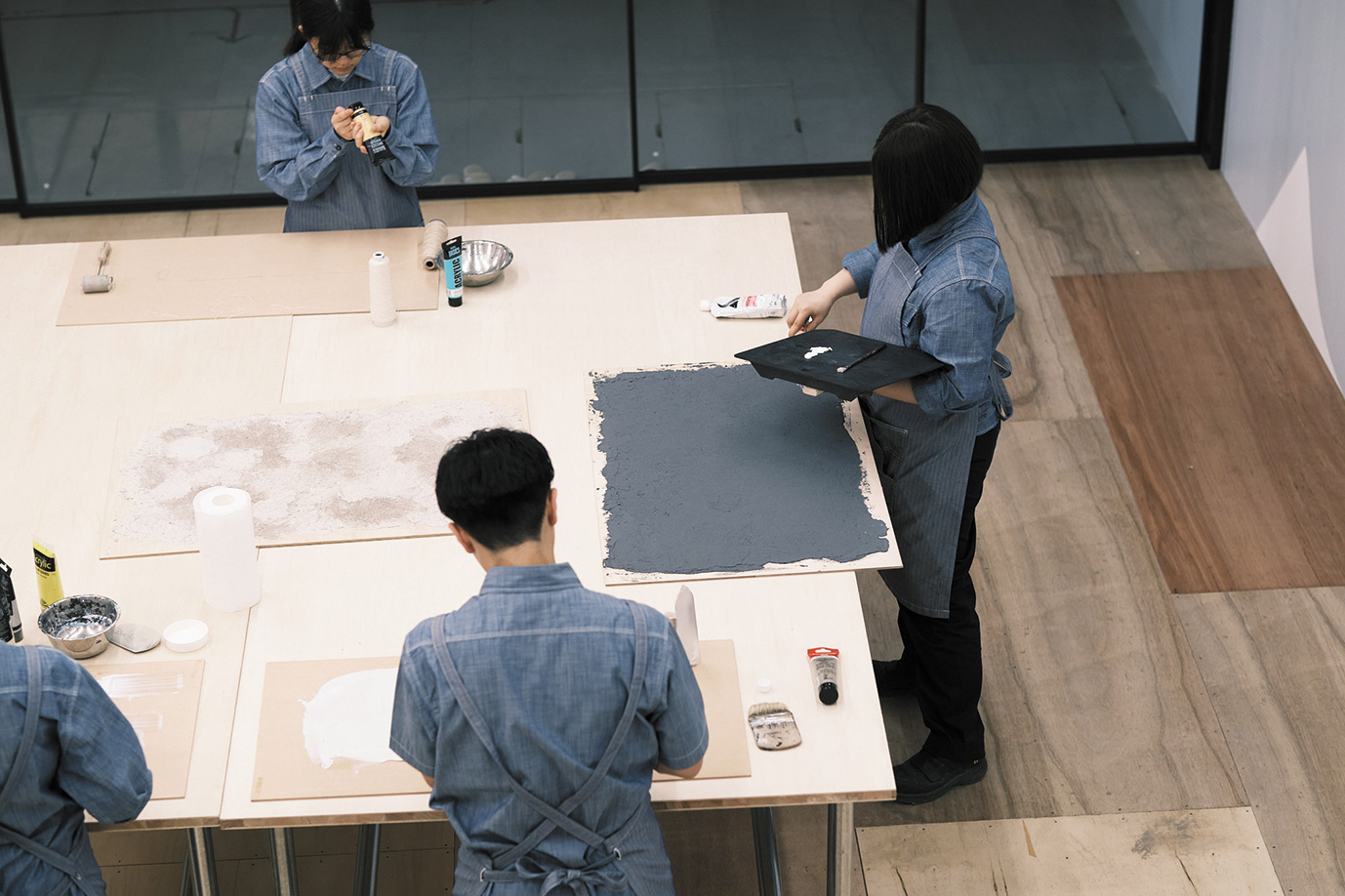

Prototypes called “babies” are created in Lab 1 for use in presentations to customers.

Wallpaper printing plates stocked in great quantities.

A wallpaper design created by crushing actual stones.

Creative production activities are carried out in the open, high-ceilinged Lab 2. The large, multipurpose space serves as a venue for prototype creation, design discussions, presentations, and more.

A loft space stocked with a library of design works offering helpful hints and ideas.

Last year, 3A Co., Ltd. expanded its facilities with creative rooms intended to facilitate the exploration of new possibilities for wallpaper and the development of highly original designs. Lab 1 and Lab 2 serve as environments where prototypes and samples of color tones and textural designs can be created and new methods involving collaboration between in-house planning staff and outside designers can be developed.

“Providing wallpapers aptly suited to the times requires delivering new forms of expression and potential added value on an ongoing basis, without being constrained by conventional modes of thinking. We have adopted the slogan ‘Create wow all (=wall)’ to represent our mission to deliver a sense of wonder and excitement to people worldwide with our provision of richly creative wallpapers,” President Maruyama tells us.

The company has continuously explored new forms of expression combining the latest technologies. These approaches range from digital printing, which allows low-volume production and enables a diverse range of expression with an unlimited number of colors, as it does not require the use of printing plates, to fleece (non-woven fabric) wallpaper, which peels off neatly, along with being easy to apply. The next challenge for the company is helping to build a more sustainable society.

“Our theme over the next several years will be working to reduce our environmental impact. One of these efforts will be developing wallpapers using raw materials with lower environmental impact. Another will be putting in place a system to collect used wallpaper for recycling and reuse. With the issues involved with sorting and collection here, it will likely take time to reach systematic implementation. Yet, this is something we must move forward with. As a start, we are working to separate the waste we generate in our wallpaper production into paper and vinyl chloride, and recycling the paper for use as paper-based cat litter,” says President Maruyama of the vision he has had for some time now.

The challenge President Maruyama has taken on to explore further possibilities to expand the appeal of wallpaper and sow the seeds of excitement in the minds of those who lay their eyes on it is still just in its beginning stages.

Tomoaki Maruyama

Three A Co., Ltd. CEO

|

Three A Co., Ltd. Sekiyado Factory

|