Possibilities of Haribako, enclosing a product and heart

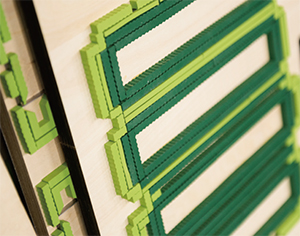

A Haribako is a box made of cardboard covered by expressive paper.

It is strong and durable even though everything is made of paper.

This tool expresses the charms, brand value, fine quality and premium sensibilities of a product by combining the form and structure of the box itself, the design of the printed papers to be added and processing, such as foil-stamping.

IWASAKI SIKI, in Hisami-cho, Nagasaki Prefecture, is a package manufacturer that produces high-quality haribako.

We will introduce the efforts and vision of this company, which continues to make new proposals both locally and nationally, with proven technical capabilities and flexible ideas.

Mr. Iwasaki (right) and his wife, Yuko, who serves as general manager of the planning division

IWASAKI SIKI Packaging Company

●Head office

201-1 Takanokashirago, Hasami-cho, Higashisonogi-gun, Nagasaki

Tel: 0956-85-2127

●Fukuoka Sales Office

3-6-29-403 Gintencho, Hakata-ku, Fukuoka-shi, Fukuoka

HP: total-package.jp

Every day we casually use many daily necessities and foodstuffs. We learn a lot of information about the use of a product from its packaging, without even needing to open the box. A package also plays an important role as a branding tool to communicate the brand’s worldview by displaying the originality and fine quality of the product, in addition to its function of enclosing products as a packaging material.

Hasami-cho, Higashisonogi-gun, is situated in the middle of Nagasaki Prefecture. It has been a production area for ceramics for at least 400 years, since the Edo period. IWASAKI SIKI is also located here. This company engages in the planning, designing, manufacturing and processing of professional handcrafted haribako and other products in an integrated manner. “We originally only made cardboard boxes to send ceramics to urban areas,” said Hirotaka IWASAKI, president of IWASAKI SIKI. Japanese ceramics are highly regarded not only for their beauty as vessels, but also as art. The area where the local industry of ceramics manufacturing has a history of continued growth is also where package manufacturers have always existed as a related business. “My grandfather founded the company in 1960, and I am its third president. However, the production volume of ceramics declined with the bursting of the economic bubble. Ceramics were often replaced by cheap imported products and the sales of packages declined considerably when I joined the company,” said Mr. Iwasaki. While package manufacturers across the country were driven out of business one after another by cheap paper boxes, Mr. Iwasaki said that to rebuild the company, he started by taking another look at its strengths. “I wondered if we would be able to develop customers beyond pottery, given that we had solid technical capabilities, experience and know-how in making craftsman-like haribako based on our many years of experience, because we would have endless business opportunities if we widened our product range to include fancy gift boxes as a packaging material.” He said that walk-in sales, which began with companies in the local area of Hasami-cho, extended to Fukuoka shortly afterward and grew into a business with manufacturers and agents in various industries across Japan, triggered by a presentation made at an exhibition in the Tokyo metropolitan area. The company has established its position as a total packaging company by making the leap forward to the manufacturing of boxes that cast the shape of the makers’ heart, instead of those that simply protect products.

A haribako is made by putting decorative sheets of paper together on an assembled box, using cardboard as the core material. The basic core material is widely used as a package for various products because it is very strong and has excellent shock absorption. “First, it is important that a haribako is made of paper. It’s light compared with other materials and its shape can be changed freely, according to the product and its concept. Because many of our products are basically only made of paper, the eco-friendliness is also an advantage,” explained Mr. Iwasaki. In addition, the design is also flexible because printed paper is put together on the core material. A haribako is used as a package for high-end and limited edition products and can fully express the charms of the product by paying a lot of attention to the color, texture and style of the paper itself.

Usually, the build-to-order manufacturing of an original haribako begins by receiving the product that will be put inside. By finely designing the box using 3D software, the company will complete it by verifying the many samples made and having many meetings with the customer. “There are a variety of requests. Some customers ask us to make a wonderful package first and then the customer will think about a product to put inside later. We feel very grateful for such requests because the value of a haribako itself is highly appreciated. However, unless we understand the product’s concept and the story leading to its commercialization, it will essentially take some time until we achieve the best finish. We think a great deal before casting the heart put in the product into its shape. As long as such heart is present, we will be able to propose a different means of expression,” said Yuko IWASAKI, general manager of the planning division. A haribako from IWASAKI SIKI also plays the role of a transmitter that communicates not only beauty as a form, but also what the producer wants to convey to the receiver.

The stock of papers ordered from Japan and abroad exceeds 300 brands.

In its studio, the company has a stock of dozens of metal foils for foil-stamping.

Wood patterns with an embedded blade are used to stamp the cardboard into the shape of a box.

Using wood patterns with an embedded blade, lines are drawn to fold the cut cardboard to fit into the shape of the development diagram and then the excess parts are cut off. After applying decorative papers with adhesive to the cardboard and assembling it carefully, one by one, haribako will be finally completed. “Although we use a customized machine for haribako, most of the process is done by hand. I think that because we are experienced with orders for haribako with a complex shape and structure which other companies would decline, our staff has naturally acquired the technical and applied skills,” said Mr. Iwasaki. One of the characteristics of the company is that there are many female employees. “I think that because a lot of our job is detailed work that requires deft hands, female employees are a better fit. Each staff member has an area of specialty, and some would like to take on more complex jobs, while others are assembling the boxes quickly, and others are good at making polygonal boxes or heart-shaped boxes. We think a great deal about staff assignments and giving them a role that brings out their individuality,” explained Ms. Iwasaki. There are approximately 50 staff members in the production division. The combination of the physical strength of the male staff in charge of making the outline and the distinct delicacy of the female staff enables the company to achieve both high quality and productivity.

.jpg)

“It’s a matter of course to beautifully bring our products to completion. We make them carefully and affectionately piece by piece.”

original brand AKERU PROJECT

“We would like to create a sensation of the moment a box is opened.” From this idea, IWASAKI SIKI, which has been developing its business dedicated to build-to-order manufacturing, has launched its original brand AKERU PROJECT. “A company won’t grow if it does the same thing, and we wanted to take on a new challenge that no other company had undertaken. Package production is one of our core businesses. We should be able to transmit high-quality products as a manufacturer with technology and production capabilities if we expand our ideas around the concept of creating a sensation, said Mr. Iwasaki.

The announced lineup consists of 160 items in five different series. They include open-minded products in classical designs that never lose their appeal, ranging from storage boxes that take advantage of the manufacturing skills acquired from haribako, to clutch bags and highly practical mats for outdoor activities. It is also surprising that all of these products are made of paper. The company also makes gift boxes to which knitting and embroidery needles (made of cardboard) are attached. “This is a product to express a message and a design which the user wants to convey through embroidery, using evenly spaced round holes that open on the box’s cover. This product is the result of collaboration with an outside creator, and we want to continue to increase such attempts in the future,” said Mr. Iwasaki. The human network that has widened through the development of original products has also spread to the build-to-order manufacturing division. One of the spillover effects is “Sewayaki Siki (caring paper package).” This is a matching service in which IWASAKI SIKI introduces a designer who has a good chemistry with a product without charge. Mr. Iwasaki said, “It would be nice if a customer were able to choose a designer according to the details of its product. We will gradually organize a system to introduce designers with different characteristics, areas of specialty and deign tastes.”

Based on the unmatched technical capabilities, expertise accumulated for many years and the production system that uniformly maintains its high quality, IWASAKI SIKI is building new business models by adding the ideas and things that the company obtained through its flexible power of ideas and many encounters. The challenge of the package manufacturer that keeps transforming has only just begun.

.jpg)

.jpg)

INFORMATION

- “AKERU PROJECT” online shop

HP: total-package.jp/akeru-project

- Presentation at exhibition

“The First Interior EXPO”

July 5 (Wed) – July 7 (Fri), 2017

Tokyo Big Sight East Hall